CEMS-5000 is a continuous emission monitoring system. It is used for the online monitoring of SO2, NOx (NO, NO2), CO, CO2 O2 and dust particles in the emission of various fixed sources, and it can be expanded to monitor the gas components of HCl, HF, NH3, CH4, H2S, Cl2, etc;

The measured gas passes through the sampling probe and heated pipeline for heating and filtration, then goes into the gas analyzer for measurement. The analyzer can be configured with different analyzing module , including UV-DOAS, NDIR, TDLAS, Electrochemical, Zirconia, etc. It can fully meet the measuring requirements for different applications. Especially for harsh environment such as high temperature, high humidity, high dust, high corrosive flue gas measurement.

With the benifit of High Accuracy, Robust Design of Analyzer, and Optimized Gas Treatment Design, it has excellent performance no matter in ultra-low concentration, or ultra-high concentration measurement.

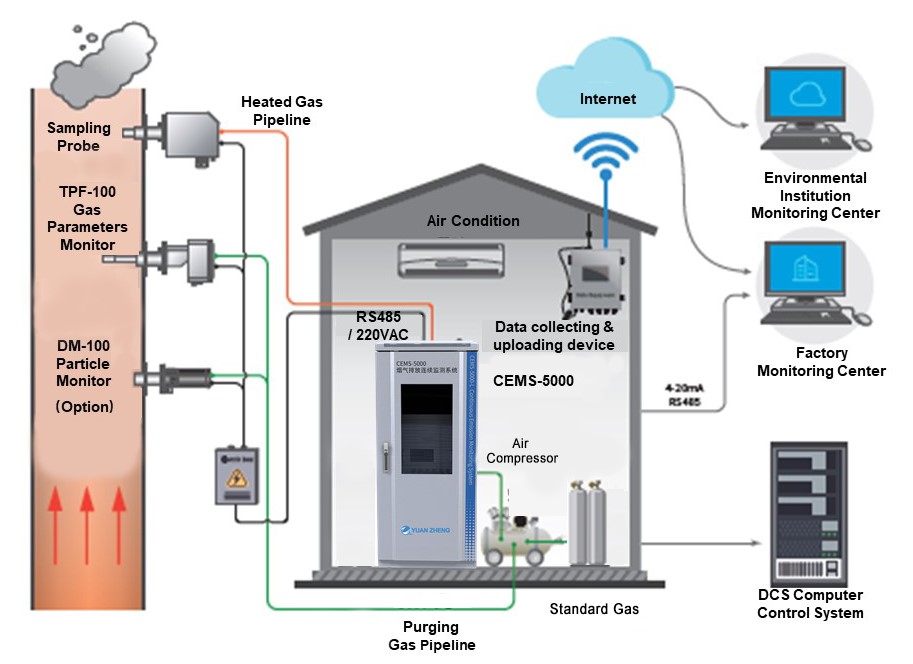

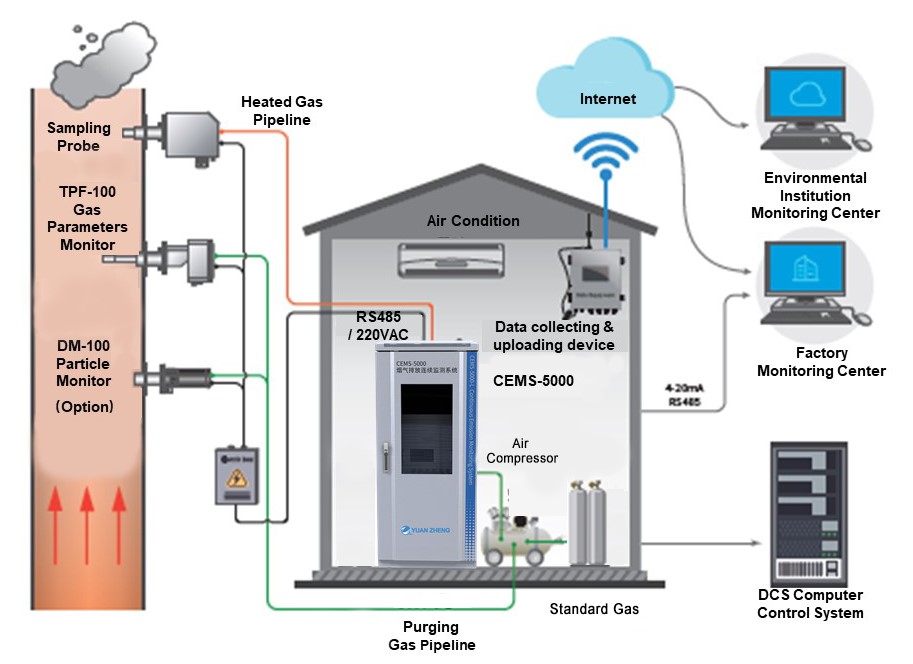

System Composition

This system consists of a sampling probe placed on the chimney, a dust particle monitor (optional),an integrated temperature, pressure, and flow monitor, a humidity meter(optional),a heat tracing pipeline connecting the chimney and the cabinet, an analytical cabinet placed in a small house, and a standard gas cylinder and air compressor.

• The sampling probe collect the flue gas samples. It is integrated with a ceramic filter to remove the dust from the flue gas;

• The heat tracing pipeline deliver the sampling gas into the analyzing system, it adopts high-temperature tracing to prevent the condensation of water vapor in the flue gas;

• The dust monitor is for real-time monitoring of the dust particle concentration in the chimney;

• The flue gas parameters monitor the temperature, pressure, and flow rate of the flue gas inside the chimney;

• The humidity monitor measure the humidity of the flue gas;

• The system cabinet is equipped with DCS system, control unit, heating unit, sampling pumps. It controls the extracting, pretreatment of the sample gas and deliver the sample gas to the analyzer for measurement;

• Standard gas is used for calibrating the analyzer;

• The air compressor produces compressed air for purging of the heat tracing pipeline, sampling probe, and gas parameters monitor.

Application

• Coal-fired power plants;

• Oil refinery plant;

• Biomass power plant;

• Municipal and waste incineration plants;

• Cement plant emission chimneys;

• Glass melting industry;

• Metallurgical Steel Plant