DM-100 Dust Analzyer adopts laser backward scattering measuring technology. The core components are all imported. It is used for continuous monitoring of emission dust concentration of pollution sources. it can be used with CEMS continuous emission monitoring system, and can also be used independently or integrated with several particle monitor to form a particle monitoring system.

Working Principle

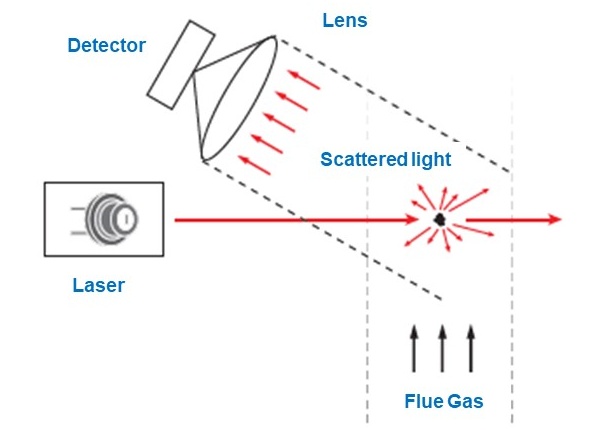

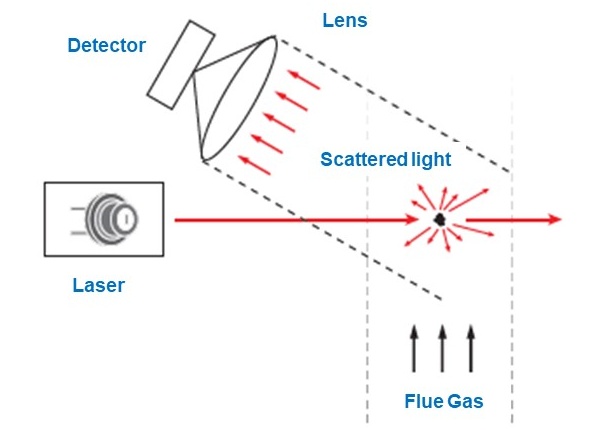

DM-100 Dust Particle Monitor utilizes the laser backscatter principle to measure particle concentration. The optical component includes a laser light source, power control, photoelectric sensors, and a scattered light reception section.

The highly stable laser emitted by the laser source is collimated and then directed enter into the flue pipe. When the laser beam encounters particle , it generates backscattered light. This scattered light is focused by a lens and then detected by a photoelectric detector. After the photoelectric signal conversion, the scattered light signal is transformed into an electrical signal proportional to the concentration of particle. Through specific algorithms, the output is the concentration value of the particle.

Features

• Laser backscatter measuring principle: real-time monitoring of particle concentration;

• Modulated laser beam: High resistance to the interference from background scattered light;

• “Tool-free” on-site installation: Support in-situ zero and span calibration;

• Infrared remote control & LCD display: Directly reading of particle concentration on-site;

• Multiple stabilization technologies: Providing rapid, reliable, and accurate monitoring of the particle concentration;

• Support Dual-measurement ranges automatically switching;

• Compact structure, easy installation, lightning proof, low maintenance. Suitable for harsh environment.

Application

Dust concentration monitoring of flue gas emission of thermal power, ferrous metallurgy, petrochemical industry, cement production, potting, waste incineration, industrial boiler; gas desulphurization and dust removal process monitoring.